Globally, structural steel is a top option in all sorts of building structures. A steel structures fabrication company may facilitate speedier construction. Steel is manufactured at a structural steel fabricator’s warehouse and then brought to the construction site. There, it is installed with ease and precision Are you ready to use a structural steel fabricator for your next construction project? Here, we’re sharing the benefits of working with a structural steel manufacturer.

Globally, structural steel is a top option in all sorts of building structures. A steel structures fabrication company may facilitate speedier construction. Steel is manufactured at a structural steel fabricator’s warehouse and then brought to the construction site. There, it is installed with ease and precision Are you ready to use a structural steel fabricator for your next construction project? Here, we’re sharing the benefits of working with a structural steel manufacturer.

Custom Structural Steel Is Economical and Faster to Install

Structural steel can create a huge reduction in the overall cost by the accumulation of savings in logistics, construction time, equipment cost, labor cost, and material cost.

Structural steel can create a huge reduction in the overall cost by the accumulation of savings in logistics, construction time, equipment cost, labor cost, and material cost.

Cost comparison studies has found structural steel to be 18% cheaper than reinforced concrete when constructing a building frame and 6% lower in terms of total building cost.

They also have the potential to reduce construction time significantly because of high precision of measurements, bolted connections which can be done by hand tools, and production which can be completed in parallel with foundation works schedule. Construction duration of Structural Steel Buildings (SSB) or Pre-Engineered Steel Buildings (PEB) are about 10% shorter compared to conventional structures.

Custom Structural Steel Is Lightweight and Safe

Structural steel building can be 30% lighter than conventional building when properly designed and constructed. This is a factor that can greatly reduce the costs of foundation works and the overall degree of construction difficulties.

Structural steel building can be 30% lighter than conventional building when properly designed and constructed. This is a factor that can greatly reduce the costs of foundation works and the overall degree of construction difficulties.

During construction, the structure can also be completed more safely due to limitations in volume of equipment & workers involved, scope of hazardous works, and time of exposure to daily risks.

Furthermore, steel is non-combustible. It does not ignite nor spread flames. It is also resistant to rust and corrosion when properly coated or jacketed, it does not mold or mildew, and resists splintering and shattering during extreme movement.

Custom Structural Steel have Pleasing Appearance and High Quality

Structural steel is visually attractive. Many architects and designers prefer to expose structural steel elements rather than conceal them with other materials. Steel also pairs nicely with other modern architectural elements like glass and fiber concrete.

Structural steel can also be fabricated into numerous shapes or geometrical configurations such as arches, twisted sections, splines, and more. Structural steel is naturally the expression of minimalist and modern architectural designs.

High quality of fabricated and manufactured structural steel can be assured due to production of all components in highly regulated, controlled, and automated environment. All steel units are precisely formed to shapes, sharp edges, dimensions, and required interconnection integrity.

Custom Structural Steel Is Strong and Durable

Steel is an excellent tensile and compressive material. Its ability to bend without easily cracking or breaking are inherent advantages of structural steel. Compared to all other materials, structural steel has the greatest ability to maintain strength and integrity during extreme events.

Being lightweight, structural steel are found to react positively to the said extremities such as strong winds. Besides, structural steel has been favored by Engineers for multi-storey buildings especially in areas with high seismic activities like Japan.

Custom Structural Steel Allows Flexible Designs

Aside from all of the benefits and reasons why you should use structural steel while building your home, it also offers you design freedom.

Architects may go beyond the box, developing ideas for homes that are distinct and distinct from the other homes on the block. With your design, you may transform your home into a work of art.

Steel Is a Sustainable and Green Material

Being 98% recyclable, steel is the most recycled material in the planet and has low carbon footprints. It is highly regarded as a green building material due to its capability to reduce wastes and pollution by significant numbers.

Steel is one of the most sustainable materials in the world because it loses none of its strength or other physical properties even after repeated recycling. Deteriorated steel and steel scraps can be melted and formed into desired forms endlessly. Demolished but sound structural members can also be transferred, re-used, or re-configured.

Additionally, steel-making process has a 95 percent water recycling rate with no external discharge making the operation conservative and environmental-friendly.

Work With a Structural Steel Fabricator For Your Next Construction Project

Reputable steel fabricators and providers always employ a recognized and dependable source with years of expertise and experience. Ideally, they provide a whole service, from product design through manufacturing and installation, relieving contractors of this burden and allowing them to focus on other elements of the construction.

If you are seeking a structural steel fabricator, go no further than ESC Steel Structures. ESC Steel Structures has been in the steel market for many years and believes in offering excellent steel to clients for any project. Visit our website to learn more about how we can help you!

High-Rise Buildings – Structural steel can incredibly resist wind, earthquakes, or other natural disasters because of its strength and flexibility. They will not break under extreme pressure. Also, when building high-rise structures, it’s entirely possible to speed up the construction process with steel.

High-Rise Buildings – Structural steel can incredibly resist wind, earthquakes, or other natural disasters because of its strength and flexibility. They will not break under extreme pressure. Also, when building high-rise structures, it’s entirely possible to speed up the construction process with steel. Commercial towers and Public Building– Structural steel is ideal for this type of construction because of its track record of delivering cost-effective and high-quality structures. Structural steel can withstand extreme weather conditions such as rainstorms, hurricanes and earthquakes. They are also adjustable and very flexible.

Commercial towers and Public Building– Structural steel is ideal for this type of construction because of its track record of delivering cost-effective and high-quality structures. Structural steel can withstand extreme weather conditions such as rainstorms, hurricanes and earthquakes. They are also adjustable and very flexible.

The bridge boosts socio-economic development by establishing vital connections and delivering supplies, especially to distant areas.

The bridge boosts socio-economic development by establishing vital connections and delivering supplies, especially to distant areas.

Panels and components of the steel bridge are easy to handle and transport can be interchanged. Being lightweight, this bridge type is guaranteed for emergency and difficult situations.

Panels and components of the steel bridge are easy to handle and transport can be interchanged. Being lightweight, this bridge type is guaranteed for emergency and difficult situations. The upgraded version of ESC-HD-100 is the ESC-HD-200 Bailey Bridge. With panel heights increased to 2.13 meters (7 feet), it can cover a maximum free span of 60.96 meters (200 feet) for single-lane width and 45.72 meters (150 feet) for double lane width. In this model, joints between panels are located alternately against the joints between reinforcement chords to reduce inelastic deformation due to oversized pinholes.

The upgraded version of ESC-HD-100 is the ESC-HD-200 Bailey Bridge. With panel heights increased to 2.13 meters (7 feet), it can cover a maximum free span of 60.96 meters (200 feet) for single-lane width and 45.72 meters (150 feet) for double lane width. In this model, joints between panels are located alternately against the joints between reinforcement chords to reduce inelastic deformation due to oversized pinholes.

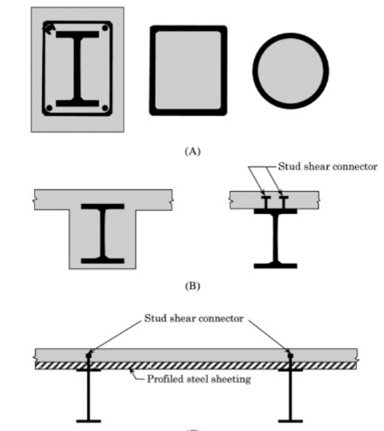

This engineering and construction method has been widely practiced over a century ago, more dominantly involving the steel-concrete connection. Concrete-encased steel sections were initially developed as composites with the purpose of overcoming the effects of fire while ensuring stability against axial and bending forces.

This engineering and construction method has been widely practiced over a century ago, more dominantly involving the steel-concrete connection. Concrete-encased steel sections were initially developed as composites with the purpose of overcoming the effects of fire while ensuring stability against axial and bending forces.

Composite Column Systems. Composite columns can either be concrete-filled steel tube or concrete-encased steel element. Either way, composite columns are advantageous as follows

Composite Column Systems. Composite columns can either be concrete-filled steel tube or concrete-encased steel element. Either way, composite columns are advantageous as follows