Case Study

Rondout Tunnel Project - New York, USA

ESC was awarded the supply 2 sets of access chambers for the construction of Rondout west branch bypass tunnel in USA. The access chambers are manufactured in accordance with ASME Section VIII – Rules for Construction of Pressure Vessel.

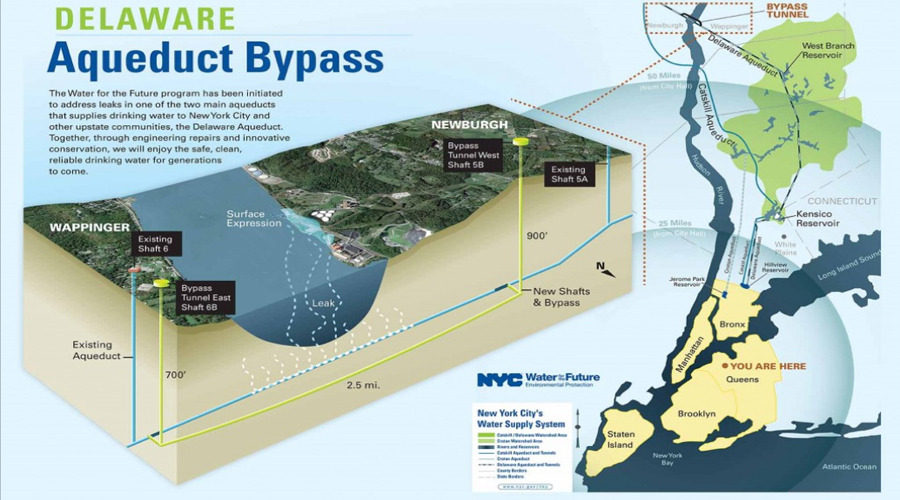

The 13.5-foot-diameter (4.1 m) rock RWB Tunnel is approximately 45 miles (72 km) long, ranges in depth from 300 to 2,300 feet (91–701 m), and operates with an internal head of up to 1,200 feet (366 m). It was constructed during the late 1930s and 1940s using drill-and-blast methods. Most of the tunnel has an un-reinforced concrete liner. In areas of poor ground conditions and significant groundwater inflow during construction, steel “interliners” were incorporated in the lining system.

Since about 1970, leakage has been observed at the ground surface, especially in an area immediately west of the Hudson River near Roseton, New York. The geology in this area of the alignment is complex. The depth, from ground surface to the existing tunnel at the Hudson River, ranges from 600 to 900 feet (183–274 m).

Rondout-West Branch Tunnel (RWBT) is currently leaking between 15 and 35 million gallons per day. DEP plans to address the leaks in RWBT by undertaking the RWBT repair program, which consists of:

Constructing a bypass tunnel around the leaking areas in Roseton.

Repair of Aqueduct in Wawarsing.

Developing water supply augmentation projects.

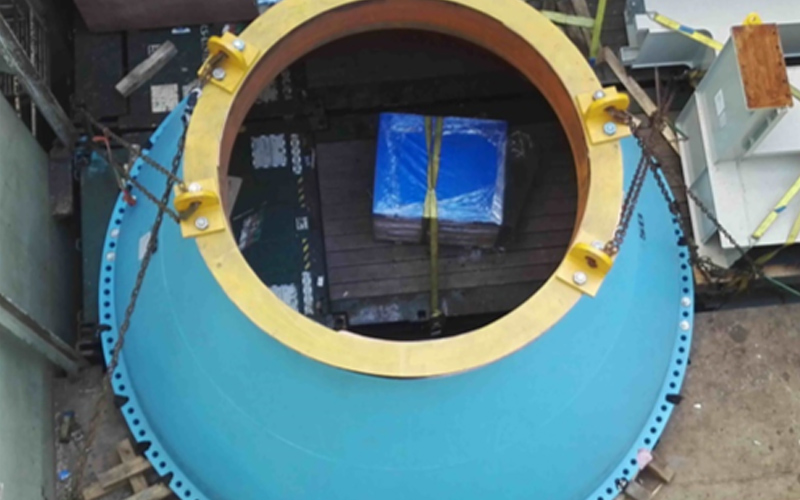

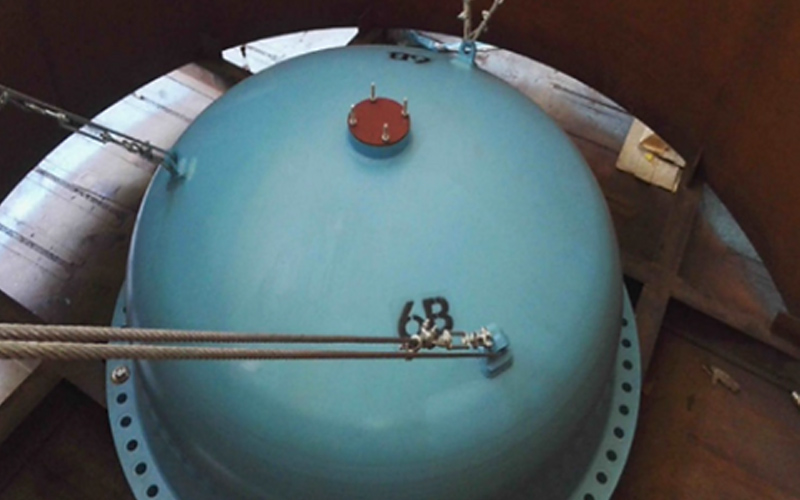

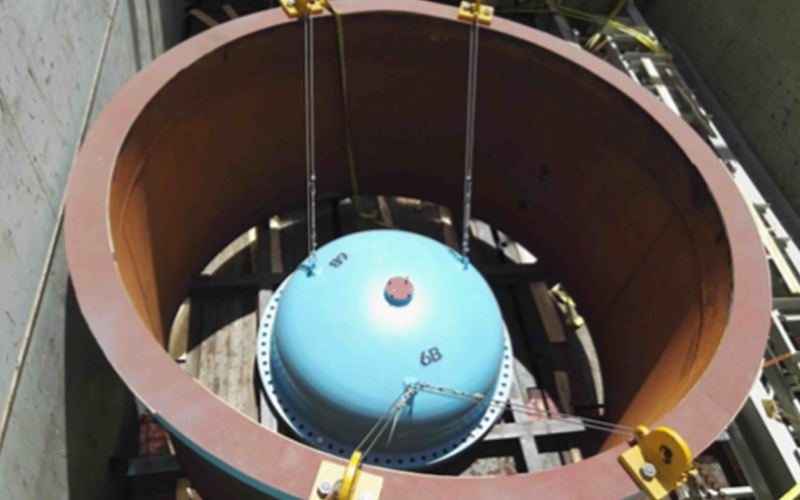

ESC was awarded the supply 2 sets of access chambers for the construction of Rondout west branch bypass tunnel in USA.

The access chambers are manufactured in accordance with ASME Section VIII – Rules for Construction of Pressure Vessel.

Each set of access chambers consist of the following components:

Shaft cap with flange

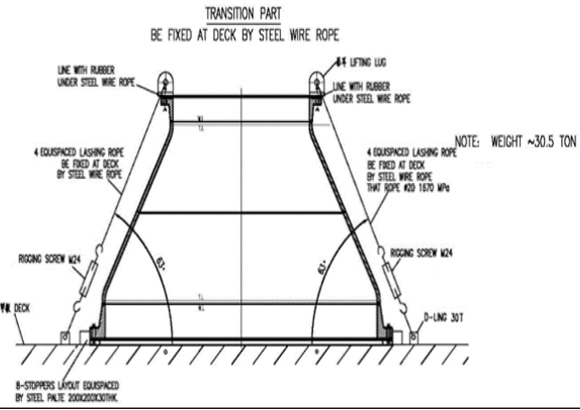

Transition fitting with flange

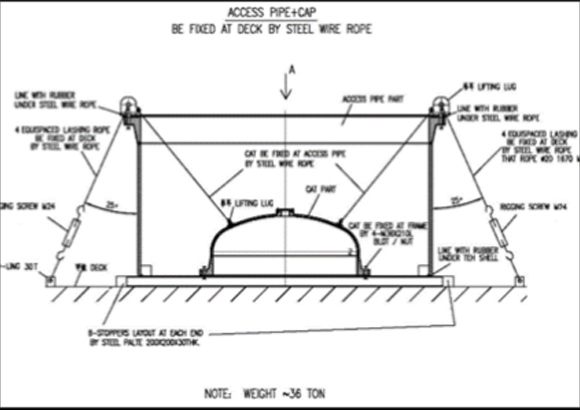

Access pipe with flange

Other accessories (stud & nut, O-ring, and plug for telltale hole)

Fabrication

Blasting and painting

packing and shipping