Every Steel Structure or Reinforced Concrete construction project might have to start with imaginations for the question “how will it look like?” but at the end of the day, reality brings us to a more valuable question – “how and what is it made of”?

At any scale, construction projects require wise and careful decisions because it is definitely a matter of no turning back. Misguided decision can hurt us in many ways – wasted time, effort, and money at the least.

To figure out better, some pros and cons of Structural Steel and Reinforced Concrete are explained in different aspects as follows:

WEIGHT

Steel framework elements has small, compact cross-sections making them approximately 60% lighter than concrete. Reinforced concrete members are bulky and may reach 2700 kg/m³ in weight.

COST

Steel Structure is economical. Huge portion of the market supply comes from recycling, making steel much cheaper than other materials. Being lightweight, it delivers huge reduction in labor cost due to easier handling and transportation and faster installation.

Concrete has many ingredients such as cement, sand & gravel, water, and various additives. And to produce a reinforced concrete member, reinforcing bars must be integrated then formed and cast to the desired section. The number of ingredients and its lengthy assembly results to high construction expenditures.

Strength

Steel Structure is economical. Huge portion of the market supply comes from recycling, making steel much cheaper than other materials. Being lightweight, it delivers huge reduction in labor cost due to easier handling and transportation and faster installation.

Japanese engineers generally refuse to use concrete for above-grade structures because it is rigid, weak and heavy, and quality control is a difficult task to perform. Compare to a Steel Strucure.

Construction

Design

Concrete can be easily formed into limit-less desirable shapes but unlike steel, they have limited capability to span huge heights and distances. Steel Structure members can be laid-out in long segments without the need of intermediate supports, eliminating obstructions thus maximizing spaces.

SAFETY

Sustainability & Environmental Impact

How About Combination of Steel Structures and Reinforced Concrete?

BUT, what if the two materials are used together in putting up a composite structure? Will it be as strong as it gets. This is what to find out in the next part.

______________________________________________________________________

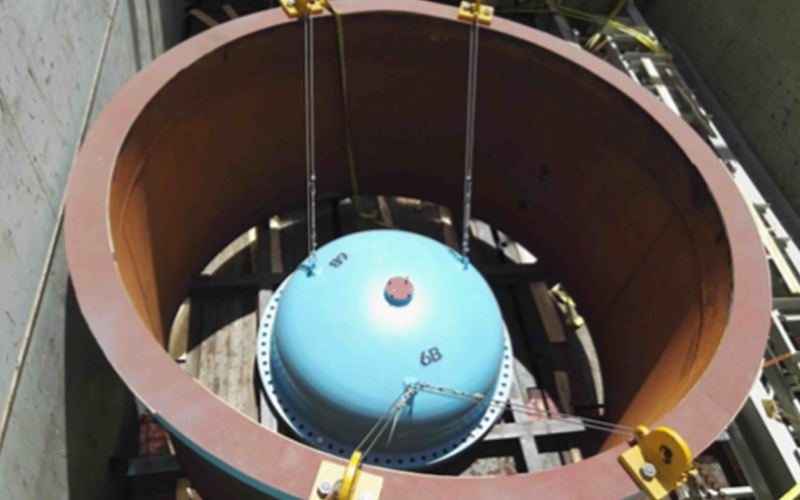

Still Need Help? ESC Steel Structures is always ready to serve you. Please visit www.escsteelstructures.com to view our full range of steel structure capabilities and project highlights in: Bridge Structures, Pre-engineered Buildings, Port & Offshore Structures, Offshore Platforms, Pressure Vessels, Steel Bridges, Mining Excavation, Steel Towers, Rail Infrastructures, and others.